Atom Under The Microscope

Electron & Atomic Force Microscopy

What is an Atom?

Essentially, an atom is the smallest unit of an element that retains the properties of the same element (iron, copper, carbon etc). This means that divided further, its components (electrons, protons, and neutrons) do not retain the properties of the element.

* The word atom is derived from the Greek word "atomos" which means uncuttable/indivisible.

Microscopy

Atoms are extremely small measuring about 1 x 10-10 meters in diameter. Because of their small size, it's impossible to view them using a light microscope. While it may not be possible to view an atom using a light microscope, a number of techniques have been developed to observe and study the structure of atoms.

Some of these techniques include:

Electron Microscopy

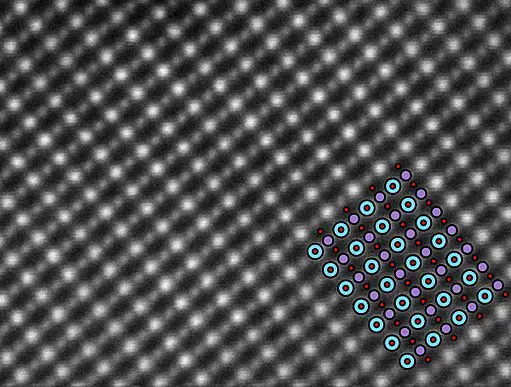

Recently, researchers have been working on improving electron microscopes to be able to penetrate down to the subatomic level in order to observe electrons.

According to one of the studies in Vienna University of Technology, researchers working on energy-filtered transmission electron microscopy (EFTEM) found out that under given conditions, it is actually possible to view images of individual electrons in their orbit.

As well, a new electron microscope (Nion Hermes Scanning Transmission Electron Microscope) was unveiled in the UK and is capable of resolutions down to the atomic level and thus capable of capturing images of individual atoms. According to the researchers, the microscope is capable of imaging objects that are a million times smaller than human hair.

Some of the techniques that have found success so far include STEM techniques.

STEM Depth

This technique has been used to observe interfacial atoms that are located between metal nanoparticles and supports. In 2015, a group of researchers used STEM Depth sectioning to directly observe gold atoms on titanium dioxide. This procedure was chosen due to the fact that on Titanium dioxide, gold tends to shown high catalytic activity.

The procedure involved the following steps:

- Precipitation of gold on Titania support in order to prepare the gold catalyst.

- Calcination of the preparation in air (or reduction) under hydrogen (H2) at high temperatures

Once the preparation was ready, the sample was observed using the aberration corrected STEM microscope (with installed JEOL 2200FS).

This technique was capable of observing the atoms, which were brighter than the Titanium atoms. By recording the focal series of Z-contrast images from the fold nanocrystal at the interfacial regions, the researchers were able to locate the atoms in 3D.

ABF_STEM (Annular Bright-Field Scanning Transmission Electron Microscopy)

While researchers had experienced some challenges, it became evident that using this technique, it was possible to observe lithium atoms (lithium with atomic number 3). This was achieved by observing such material as Lithium manganese oxide (LiMn2O4) in order to view lithium ions.

By viewing this compound/crystal under the microscope, the

researchers could identify the different atoms (Li, Mn, and O) and thus

identify the lithium atoms on their own. However, this was only possible when

using the STEM microscope with a resolution of 0.1 nm or lower with corrected

spherical aberration.

* Recently, a student from the University of Oxford captured the image of a single, floating atom (strontium atom) using typical camera.

Scanning Tunneling Microscope

Main parts of the scanning tunnelling microscope:

- Sharp metallic tip - This is the part that is brought close to the sample (conductor)

- Scanning control, distance control - Controls the distance between the tip and sample surface and regulates scanning

- Computer for data processing and display - Output through which information is relayed. The computer also controls the piezoelectric tube.

- A piezoelectric controlled probe - During operation, the Piezoelectric will contract and expand with varying voltage, which in turn controls both the horizontal and height positions of the scanning tip.

The scanning tunneling is one of the techniques that was developed in the earl 1980s in Switzerland by Gerd Binnig and Heinrich Rohrer.

Essentially, this technique works by passing an electronic wave over the surface of the sample (element). By passing the wave of electrons on the surface of the sample, it becomes possible to position and thus detect the atom.

Working Principle

The scanning tunneling microscope has a small sharp/pointed metal tip that is brought very close to the surface of the sample. Here, the distance between the pointed metal tip and the sample is very close that they almost come in contact (about 1 nm).

With the tip very close the surface of the sample, the two are put under a small voltage, which allows a tunneling current to flow. With current flowing between the two, the surface is scanned to reveal a three dimensional picture of the surface, and thus the general appearance of atoms on the surface of the sample.

With this technique, electrons may also flow only from the tip of the pointed metal to the sample or from the sample to the tip. As the current originates from the metal tip, the scanner moves it (the tip) rapidly across the surface of the sample.

Once the metal tip locates an atom at the surface of the sample, electrons flow between the two changes while the computer registers the change. This change is recorded in the x-y position, as the tip continues moving and identifying more points of atom locations that are then registered.

These points on the surface represent the presence of the atoms that can then be scanned and viewed. This in turn makes it possible to identify their structure.

Electron Tunneling

What is Electron Tunneling?

From quantum physics, electrons should not be able to pass through given barriers (such as air). However, when they are able to pass through such barriers, the electrons produce what is refered to as a tunneling current. This makes it possible to observe various materials at the atomic level/scale.

By bringing the metallic tip of the scanning tunneling microscope very close to the surface of the sample material (conductor), a small gap that contains is left between the tip and the material surface. However, electrons are able to tunnel through the gap producing an electric current that can be detected and measured.

As the metallic tip is passed across the surface of the sample material, the current produced will vary depending on the peaks and valleys of the surface (surface profile) which allows for individual atoms to be located.

* Unlike the light microscope, the scanning tunneling microscope relies on electrons to locate and position atoms

* Rather than behaving as particles, electrons in this technique behave like a wave, which allows them to pass through the barrier

Operation Modes

With the scanning tunneling microscope, there are two main modes of operation used when studying the surface of the sample material. This includes the constant current mode and the constant height mode.

Constant Current Mode

As already mentioned, the amount of current between the metallic sharp tip and the sample surface varies depending on the surface profile (peaks and depths) if the distance between the tip and the surface is more, then there is little current. However, a short distance between the two will result in more/high current.

In the constant current mode, the current level is kept at a constant by moving the tip up and down as it moves across the surface of the sample to retain the same height. Given that the contours across the sample surface change, adjusting the tip by moving up and down allows for the current to remain constant.

With this technique, atoms can be located and positioned by recording the adjustment of the metallic tip (as it vertically moves up and down).

Constant Height Mode

For this mode of operation, the height of the tip does not change as it moves across the surface of the sample. As a result, only the current changes depending on the contours of the sample surface.

For this technique, atoms are located and positioned by the recording of the changing current.

Atomic Force Microscopy

Atomic force microscopy is also a type of scanning probe microscope that works by recording such properties as height, magnetism and friction.

By measuring these properties using a probe, it becomes possible to get the image of a given surface area. This technique was developed with the aim of improving the limitations of scanning tunneling microscope given that atomic force microscope is capable of studying such non-conductive materials as proteins (the scanning tunneling microscope is only used to investigate conductive material).

Main parts of the AFM

- Sharp tip (Probe) - The sharp tip or AFM (atomic force microscope) probe moves over the surface of the sample for scanning

- Optical lever - The optical lever allows for measurements to be made by measuring deflections of the cantilever

- The piezoelectric scanner - This part serves to move the sharp tip across the surface of the sample

- Cantilever - This is the soft girder on which the tip is attached

Working Mechanism

The atomic force microscope probe (made through micro-fabrication) is very sensitive and is the part that comes in contact with the sample.

As the tip moves across the surface of the sample, it senses its contours. As such, it does not rely on electrons or light to view the sample surface. This has been shown to be one of the biggest strengths of this technique, allowing for higher resolution and efficiency.

When the AFM tip approaches the sample surface, attractive force between the surface of the sample and the tip results in the cantilever bending towards the surface of the sample. However, as the tip comes closer to the proximity of the sample, deflection results from repulsive forces causing the cantilever to bend away from the sample surface (this is why the cantilever has to be very soft and flexible).

Whereas the z-scanner moves the cantilever up and down, the x-y scanner moves the sample back and forth. These movements make it possible to scan the entire surface area of the sample. And so, a position detector/sensor (optical lever) in place records the bending of the cantilever.

The position sensor records the beam changes that are reflected off the top of the cantilever. As the cantilever moves, there are also changes in the beams, which are all recorded. With all these changes, the topography of the sample surface is recorded to give an accurate representation.

* A laser diode produces a laser beam, which is reflected off the flat back of the cantilever and on to the photo detector (position detector) As the sharp tip moves across the surface, it causes the cantilever to move, which in turn causes changes in the deflected beam. This is then detected as varying light intensity.

The movement of the AFM tip is typically controlled by a scanner that is made up of piezoelectric material and thus the piezoelectric scanner - This type of material (piezoelectric material) is largely preferred for both AFM and STM due to the fact that they move the tip in a very precise manner along the x, y, z axes.

For such small displacements as the tip moves across the sample surface, this material allows for very good reproducibility.

Modes of Operation

Contact Mode

In contact mode or contact AFM, the probe/tip comes in contact with the sample surface and slightly dragged across the contours of the surface. As the probe moves across the surface while in contact, it causes deflections of the cantilever, which in turn allows for the surface to be scanned using laser beams.

While this method has been shown to have the advantage of being easy to use due to its simple set up, it has several disadvantages including damaging the surface of the sample as well as the probe itself. In particular, "dragging" the tip across the surface causes it to be gouged, which in turn may affect the quality of the final image.

Here, it is worth noting that in some cases, the sample surface is scratched intentionally. For instance, some researchers will scratch the sample surface using the contact mode in order to deposit other samples in the scratched region. This is particularly the case with some form of electroplating. The technique is also used for measuring friction at the nanoscale. This largely involves scratching the surface by dragging the cantilever tip on the sample surface.

Non-contact Mode

Also known as dynamic force microscopy (DFM) non-contact atomic force microscopy involves passing the probe very close to the sample surface without really dragging it on the sample surface.

Here, the cantilever oscillates just above the surface as scanning takes place. A precise high speed loop ensures that the cantilever, and thus the tip does not crash onto the surface of the sample. With the tip being close to the surface, van der Waal forces that result decreases the cantilever's resonance frequency, which together with the feedback loop ensures that a constant oscillation is maintained.

As the tip oscillates and moves across the surface of the sample, scanning allows for a 3-D image of the surface to be constructed.

This technique has a big advantage in that the sharpness of the tip is maintained while the sample remains undamaged. Given that the tip is protected from damage, it can be used over and over again while providing quality images of the sample surface.

Tapping Mode

The tapping mode involves having the tip of the cantilever touch the sample surface only for a short period to time. This technique helps prevent problems associated with lateral force and dragging that occurs across the surface of the sample.

The cantilever tip oscillates at a higher amplitude (20-100 nm), which in turn makes the deflection signal large enough for the control circuit. This technique is largely used to scan the surface of damaged samples where it reduces high resolution.

Structure

Atoms are composed of a nucleus (containing protons and neutrons) and electrons that surround the nucleus. Whereas protons have a +1 charge, electrons have a -1 charge. For all atoms, the atomic number is the number of protons while the arrangement of electrons gives the electronic structure of the atom.

* Unlike other elements, hydrogen does not have any neutrons

Return from Atom under the Microscope to MicroscopeMaster Home

References

Wenpei Gao, Shankar Sivaramakrishnan, Jianguo Wen, Jian-Min Zuo (2015) Direct Observation of Interfacial Au atoms Using STEM Depth Sectioning.

IFM – The Department of Physics, Chemistry and Biology. Scanning Tunneling Microscopy.

https://www.azonano.com/article.aspx?ArticleID=3010

https://www.nanoscience.com/files/9013/7961/8081/STM_TeachersManual.pdf

Find out how to advertise on MicroscopeMaster!

![STM topographic image of a single Co atom on Cu(111) shown in a light shaded view. Current 1 nA, sample bias -10 mV, T = 2.3 K. by NIST, Joseph Stroscio et. al. [Public domain], via Wikimedia Commons STM topographic image of a single Co atom on Cu(111) shown in a light shaded view. Current 1 nA, sample bias -10 mV, T = 2.3 K. by NIST, Joseph Stroscio et. al. [Public domain], via Wikimedia Commons](https://www.microscopemaster.com/images/STM_image_of_single_Co_atom.jpg)