Scanning Electron Microscope

Advantages and Disadvantages in Imaging Components and Applications

A Scanning Electron Microscope (SEM) is a powerful magnification tool that utilizes focused beams of electrons to obtain information.

The high-resolution, three-dimensional images produced by SEMs provide topographical, morphological and compositional information makes them invaluable in a variety of science and industry applications.

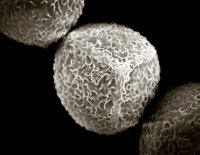

To the right is a picture of

a pollen grain viewed under a SEM.

SEM Properties

The Scanning Electron Microscope developed by professor Dr. Charles Oatlev with the assistance of graduate students in the 1950s, are one of the three types of electron microscopes (EM).

Electron microscopes utilize the same basic principles as light microscopes, but focus beams of energetic electrons rather than photons, to magnify an object.

SEMs consist of the following components:

- Electron Source

- Thermionic Gun

- Field Emission Gun

- Electromagnetic and/or Electrostatic Lenses

- Vacuum chamber

- Sample chamber and stage

- Computer

- Detectors (one or more)

- Secondary Electron Detector (SED)

- Backscatter Detector

- Diffracted Backscatter Detector (EBSD)

- X-ray Detector (EDS)

In addition, SEMs require a stable power supply, vacuum and cooling system, vibration-free space and need to be housed in an area that isolates the instrument from ambient magnetic and electric fields.

SEM Imaging

A Scanning Electron Microscope provides details surface information by tracing a sample in a raster pattern with an electron beam.

The process begins with an electron gun generating a beam of energetic electrons down the column and onto a series of electromagnetic lenses.

These lenses are tubes, wrapped in coil and referred to as solenoids.

The coils are adjusted to focus the incident electron beam onto the sample; these adjustments cause fluctuations in the voltage, increasing/decreasing the speed in which the electrons come in contact with the specimen surface.

Controlled via computer, the SEM operator can adjust the beam to control magnification as well as determine the surface area to be scanned.

The beam is focused onto the stage, where a solid sample is placed. Most samples require some preparation before being placed in the vacuum chamber.

Of the variety of different preparation processes, the two most commonly used prior to SEM analysis are sputter coating for non-conductive samples and dehydration of most biological specimens.

In addition, all samples need to be able to handle the low pressure inside the vacuum chamber.

The interaction between the incident electrons and the surface of the sample is determined by the acceleration rate of incident electrons, which carry significant amounts of kinetic energy before focused onto the sample.

When the incident electrons come in contact with the sample, energetic electrons are released from the surface of the sample. The scatter patterns made by the interaction yields information on size, shape, texture and composition of the sample.

A variety of detectors are used to attract different types of scattered electrons, including secondary and backscattered electrons as well as x-rays.

Backscatter electrons are incidental electrons reflected backwards; images provide composition data related to element and compound detection. Although topographic information can be obtained using a backscatter detector, it is not as accurate as an SED.

Diffracted backscatter electrons determine crystalline structures as well as the orientation of minerals and micro-fabrics.

X-rays, emitted from beneath the sample surface, can provide element and mineral information.

SEM produces black and white, three-dimensional images.

Image magnification can be up to 10 nanometers and, although it is not as powerful as its TEM counterpart, the intense interactions that take place on the surface of the specimen provide a greater depth of view, higher-resolution and, ultimately, a more detailed surface picture.

SEM Applications

SEMs have a variety of applications in a number of scientific and industry-related fields, especially where characterizations of solid materials is beneficial.

In addition to topographical, morphological and compositional information, a Scanning Electron Microscope can detect and analyze surface fractures, provide information in microstructures, examine surface contaminations, reveal spatial variations in chemical compositions, provide qualitative chemical analyses and identify crystalline structures.

SEMs can be as essential research tool in fields such as life science, biology, gemology, medical and forensic science, metallurgy.

In addition, SEMs have practical industrial and technological applications such as semiconductor inspection, production line of miniscule products and assembly of microchips for computers.

SEM Advantages

Advantages of a Scanning Electron Microscope include its wide-array of applications, the detailed three-dimensional and topographical imaging and the versatile information garnered from different detectors.

SEMs are also easy to operate with the proper training and advances in computer technology and associated software make operation user-friendly.

This instrument works fast, often completing SEI, BSE and EDS analyses in less than five minutes. In addition, the technological advances in modern SEMs allow for the generation of data in digital form.

Although all samples must be prepared before placed in the vacuum chamber, most SEM samples require minimal preparation actions.

SEM Disadvantages

The disadvantages of a Scanning Electron Microscope start with the size and cost.

SEMs are expensive, large and must be housed in an area free of any possible electric, magnetic or vibration interference.

Maintenance involves keeping a steady voltage, currents to electromagnetic coils and circulation of cool water.

Special training is required to operate an SEM as well as prepare samples.

The preparation of samples can result in artifacts. The negative impact can be minimized with knowledgeable experience researchers being able to identify artifacts from actual data as well as preparation skill. There is no absolute way to eliminate or identify all potential artifacts.

In addition, SEMs are limited to solid, inorganic samples small enough to fit inside the vacuum chamber that can handle moderate vacuum pressure.

Finally, SEMs carry a small risk of radiation exposure associated with the electrons that scatter from beneath the sample surface.

The sample chamber is designed to prevent any electrical and magnetic interference, which should eliminate the chance of radiation escaping the chamber. Even though the risk is minimal, SEM operators and researchers are advised to observe safety precautions.

Hitachi's Scanning Electron Microscope

Hitachi High-Technologies, formed in 2001, manufactures a variety of science and technology related products.

Some Hitachi products include spectrophotometers, a variety of analyzers, inspection equipment, electronic devices, and semiconductor products as well as a line of microscopes.

They currently manufacture three scanning electron microscope models:

- S-3700N, an analytical style SEM ideal for studying large, heavy and tall samples

- S-3400N, a user-friendly, more compact model that utilizes new technology in electron optics

- SU1510, a compact, high performance SEM that can handle large samples and provides high-resolution imaging

A Scanning Electron Microscope provides detailed surface data of solid samples.

SEMs take incidental electrons and focus them onto a specimen; the electrons that scatter off the surface following this interaction can be analyzed with a variety of detectors that provide topographical, morphological and compositional information regarding the surface of a sample.

Although SEMs are large, expensive pieces of equipment, they remain popular among researchers due to their wide range of applications and capabilities, including the high-resolution, three-dimensional, detailed images they produce.

Check out a great page on Nanotechnology here

Transmission (TEM) - check out one of the most powerful microscopic tools available to-date, capable of producing high-resolution, detailed images 1 nanometer in size.

Cryo-Electron - is a type of transmission electron microscopy that allows for the specimen of interest to be viewed at cryogenic temperatures. Check it out.

Cryo- Electron Tomography - Resolution, Advantages and Advances

Virtual - provides a simulated microscope experience via a computer program or Internet website for both educational and industrial applications and are easily operated and accessible.

Take a look at how Electron Microscopy compares to Super-Resolution Microscopy.

Taking a look at Viruses under the Microscope and answering the question, what are viruses?

As well as Atom under the Microscope and DNA under the Microscope

Electron microscopy (SEM and TEM) images of SARS-CoV-2 - Covid 19

Also learn about Near Field Scanning Optical Microscopy

For information about the Transmission Electron Microscope click here.

Return from Scanning Electron Microscope to Electron Microscope

Return from Scanning Electron Microscope to Best Microscope Home

Find out how to advertise on MicroscopeMaster!