Cement under a Microscope

Petrographic - Observations and Discussion

Background

Cement is a very fine and soft substance that is used as a binder in construction. Here, it serves to bind sand and gravel (to form concrete) which can then be used in the construction of bridges, roads, dams, and buildings, etc. According to some reports, the powder is suggested to be fine enough to pass through a sieve capable of holding water.

In the cement industry, microscopy has proved to be one of the most valuable tools used for examining every stage of cement manufacture to ensure that a high-quality product is produced. This may involve an inspection of a thin powder mount, a thin section of cement paste of cement clinker, etc using a number of techniques suitable for the sample under investigation.

Whereas a polished section of cement clinker is examined using transmitted light under the microscope, transmitted light is used to observe and examine thin sections.

These techniques, which can be easily carried out within a few minutes, allow technicians to study such details as the size of crystals, morphology, distribution as well as abundance of the sample and thus rate the quality of different batches.

Large clusters of free lime in the sample is evidence of coarse limestone particles as well as coarse Alite which is indicative of a slow rate of heating. Therefore, microscopy is a valuable tool in quality control which ensures that consumers receive a quality product for construction purposes.

One of the first people to study cement under the microscope was Le Chatelier (in the 1870s) using a polarizing microscope. Using the microscope, Le-Chatelier was able to study the properties of cement before and after it converts into a hardness state in what is today commonly referred to as the soundness test of cement. Depending on curing conditions, Le-Chatelier noticed that the absolute volume hydrated cement paste could be less than that of water used to hydrate it.

Through his investigation of cement clinker, he also noticed tricalcium silicate to be the primary component of clinker which led him to the conclusion that this is was the most important cementing agent. Later, studies conducted by Tornebohm, a Swedish researcher, helped in the identification of four types of crystals in clinker (belite, celite, felite, and alite) as well as isotropic residue. These early studies laid the foundation for further analysis and study of cement using microscope techniques.

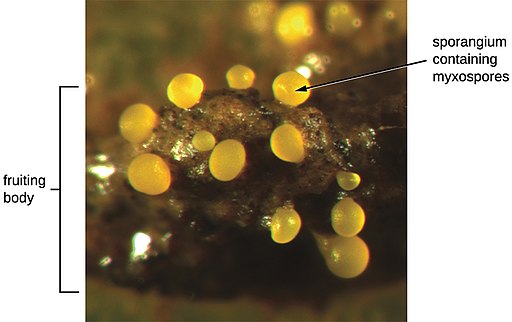

* Cement clinker are nodular material normally made by heating ground limestone and clay. These nodules are then ground into a fine powder to produce cement. Therefore, cutting and grinding a nodule of this material would give you an idea of how cement looks under the microscope.

* Although several types of microscopes are used for different analysis processes, the petrographic microscope is the most widely used microscope technique for cement microscopy.

Petrographic Microscope

Also known as a polarizing microscope, a petrographic light, is a compound microscope that uses polarized light for the purposes of analyzing and identifying rocks and minerals. Using this technique, it's possible to identify such characteristics as the texture and features associated with given minerals and rocks, etc, which makes the microscope such a valuable tool in quality control in the cement industry.

Some of the main parts of a petrographic microscope include:

· Illuminator - Located at the base of the microscope, the illuminator is used for transmitted light microscopy

· Substage assembly - Located below the stage of the microscope and consists of the parts that regulate the light. These include the condenser, light filters, lower polarizer, and diaphragms

· Stage - This is the platform on which the section/specimen is placed for observation. As compared to many other microscopes, the stage of a petrographic microscope can rotate, which allows the sample/specimen to rotate during observation

· Polarizers - The two polarizers of a petrographic microscope include the polarizer located in the substage assembly and the analyzer which is located between the objectives and Bertrand lens. The two polarizers are normally at a 90-degree angle to each other

Some of the other parts include:

- Focus knobs (the coarse and fine focus knobs)

- Revolving nosepiece and microscope objectives

- Eyepieces and oculars

- Camera

- Accessory plates (often inserted above the objectives for advanced optical tests)

Some of the other microscope techniques used for cement analysis include:

Cement under a Microscope

Objectives

For this experiment, you will make thin sections of cement clinker for microscopy.

By the end of this activity, you should be able to:

- Effectively prepare sufficiently thin sections for microscopy

- Identify various crystalline minerals present in the sample

- Understand how to use a petrographic microscope

Requirements

- Clinker nodules

- Glass or plastic vial (about 25mm in diameter)

- Liquid resin (epoxy)

- Microwave

- Diamond saw

- Lapping wheel with fine abrasive - Having lapping wheels with successively finer abrasives are recommended

- Non-aqueous solvent

- Petrographic microscope

- 1,2-propanediol

- Slide adhesive

Procedure

· Place the clinker nodules in the vial - If the nodules are too big, you can crush them down to get smaller nodules and place them in the glass/plastic vial

· Place the vial under vacuum to add the resin - Here, you can gradually release and apply vacuum while adding the resin in order to ensure that the resin penetrates the pores of the clinker. This is particularly important because it will eliminate air bubbles as the resin fill up the pores

· Place the sample (in the vial) in a microwave oven and allow it to harden at 40 to 60°C - This hardens the resin in preparation for cutting

· Once the resin has hardened, cut the block using a diamond saw to make as thin sections as possible

· Glue the section onto a clean microscope slide using a slide adhesive in preparation for grinding

· Using a non-aqueous liquid lubricant, grind the surface (the exposed surface) of the sections on the lapping wheel - Here, it's important to use successively finer abrasives in order to make good sections for microscopy

· Wash the surface of the section using a non-aqueous solvent and allow drying - This may involve using isopropyl alcohol spray and drying with forced warm air

· Once the slice has been sufficiently polished, add a drop of epoxy and carefully press a cover slip (at an angle) on the drop to cover the thin section

* Avoid excessive heating/drying in order to prevent cracking

Mounting the Section (Petrographic Microscope)

· With the stage lowered, turn the rotating turret to set the low objective (40x objective) in place

· Before mounting the slide, make sure that the stage is centered

· Place the slide on the microscope stage

· With the sample also centered on the stage, turn the coarse and fine adjustment knobs to bring the image into focus

· You can rotate the stage using the stage knob to observe different fields of the specimen

· Switch to high power and observe the slide (you can use 400 magnification)

· Record your observations

Observations

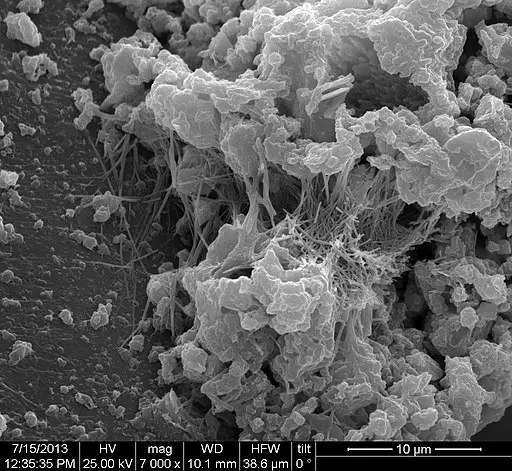

* If a stereo microscope is used to observe a sample of cement, it's not possible to distinguish between individual particles because cement particles are extremely small. For this reason, you may only be able to see a cluster image

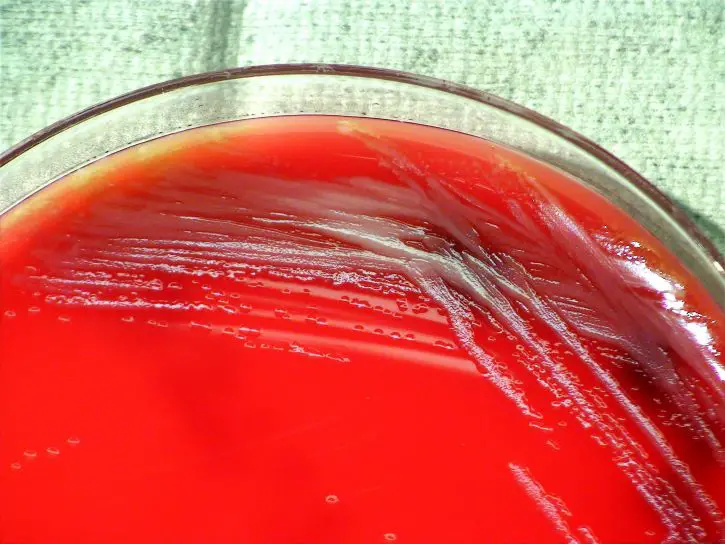

* If a fluorescent microscope is used to observe a section of concrete, it's possible to see the large particles of sand and while cement will appear as a dark matrix between the particles

Discussion

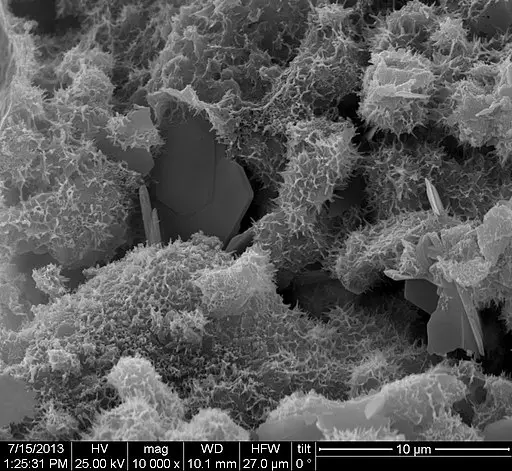

While the process involved in the preparation of cement clinker is not complicated, several precautions have to be taken to ensure good results. While cutting and grinding the clinker, it's worth noting that the single crystals are very small in size. For this reason, the sections/slices have to be finely ground.

For the most part, sections of between 0.025 and 0.015mm in thickness are recommended. On the other hand, images have been shown to be highly improved when high-index resin, such as Hyrax resin (rather than conventional balsam) is used.

During the preparation process, it's also important to avoid using water. In the section above (sample preparation), you will notice that non-aqueous liquid lubricants are used in place of water. This is because water results in the hydration of the sample, which can affect the end results. When samples are hydrated, then the condition of the constituents are altered, which may affect the preparation process.

Conclusion

As mentioned, preparing a thin section is not a complicated process. However, it requires that you take care of each step in order to produce a sufficiently thin slice without damages that would otherwise affect the quality of results. Here, preparing several slides is often recommended in order to have better chances of having a few good slides.

In this experiment, the procedure for preparing a thin slice of cement clinker was outlined. However, this procedure can also be used to prepare a thin slice of concrete for comparison. Given that concrete also contains cement, this would allow you to compare the slide with a slide of cement clinker. Moreover, different types of microscopes can be used in order to compare the images.

More ideas below:

Snowflakes

Ant

Glass

Paper

Cement

Return from Cement under a Microscope to MicroscopeMaster home

References

Herbert Insley and Van Derck Frechette. (1955). Microscopy of Ceramics and Cements: Including Glasses, Slags, and Foundry Sands.

Jeremy Ingham. (2010). Geomaterials Under the Microscope: A Colour Guide.

Paul Stutzman. (2020). Specimen Preparation.

Zahra Ahmadi. (2017). Kiln Condition Investigation Based on Microscopically Study, Ono Method and

Bouge Calculation in Fars Cement Factory, South West Iran.

Links

https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/pccp/04150/chapt11.cfm

https://www.nightsea.com/articles/concrete-thin-section-fluorescence/

Find out how to advertise on MicroscopeMaster!